Linear motors offer high speed, high force, and high precision. The choice of linear motor significantly impacts system performance and efficiency. This blog will help you select the ideal linear motor for different purposes, focusing on iron-core and iron-less linear motors

Linear motors have significantly enhanced the dynamic capabilities of various applications. The most suitable motor depends on your application's unique needs. Prodrive Technologies, a leading provider of linear motor solutions, offers Iron core and Ironless linear motors for a wide range of demands. Next to a large portfolio of off-the-shelf products, Prodrive Technologies can provide customizations to be the best fit for your application.

An overview of linear motors

A linear motor is an electric motor that operates in a straight line, providing direct linear motion as opposed to the rotational motion of traditional electric motors. Linear permanent magnet motors offer high precision, speed, and acceleration, making them the perfect choice for high-tech applications. The linear motor consists of two separate parts: the magnet array (static part) and coil unit (moving part). This technology can provide contactless and frictionless operation which leads to higher accuracy and, optionally vacuum-compatible solutions.

Iron core or ironless?

One of the most important decisions to be made is the choice of either an iron core or ironless linear motor. Both types operate on the same principle, but their construction is different. That leads to different performance levels, form factors, and side effects.

Iron core linear motors

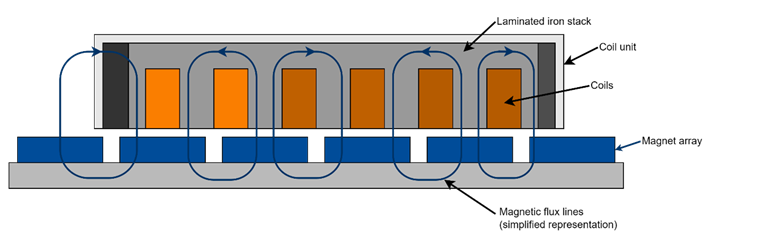

Iron core motors consist of a magnet array or track (secondary part) and a coil unit (primary part) where the coils are embedded in a laminated iron stack. These motors are known for their high force density due to the iron's ability to focus and enhance the magnetic field. Therefore, these motors only require a single array of magnets, and the magnetic field of these magnets is flowing through the laminated iron stack of the coil unit (see Figure 1). Hence, for the same output force, iron-core motors are often the cheaper solution.

Figure 1. Cross section of an iron core motor.

This laminated iron stack is important. First, it creates a significant attraction force from the coil unit towards the magnet array (orthogonal to the direction of movement). This attraction force can be advantageous when a certain preload is needed on the bearing system. Second, it creates additional cogging forces and force ripples since the iron stack has preferred positions with respect to the magnet array. This effect is minimized by applying skewing on the magnet array and proper dimensioning of the lamination stack.

Iron core motors are often the proper choice when positioning accuracies are in the order of 1-10 µm or above and when the selected bearing technology can cope with the large attraction forces.

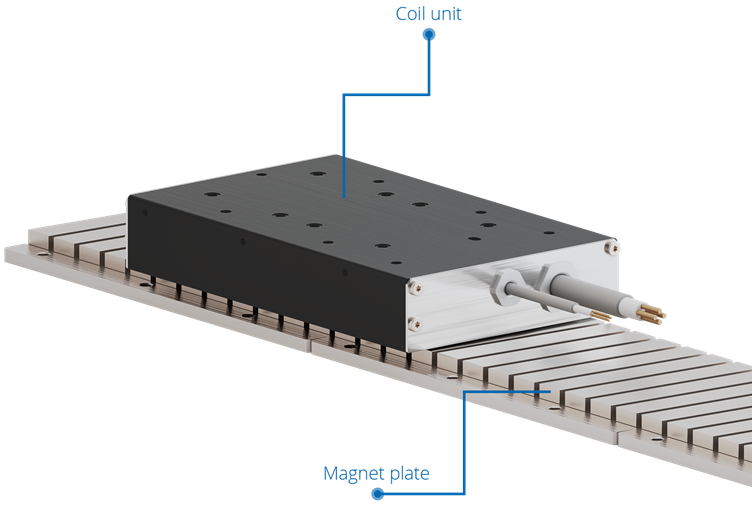

Figure 2. “Chiron” Iron-core linear motor.

Prodrive Technologies' Iron core motors such as the Chiron series (see Figure 2) offer excellent continuous and peak force. The Chiron series is ideal for applications requiring high force or high speed such as machine tools and pick & place machines.

Ironless linear motors

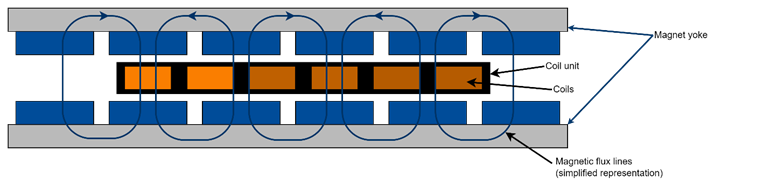

The coil unit of ironless linear motors does not contain the laminated iron stack or any other magnetic material. The magnetic field is instead closed by a second magnet array which together with the first magnet array forms the ‘magnet yoke’ (see Figure 3).

Figure 3. Cross section of an ironless motor.

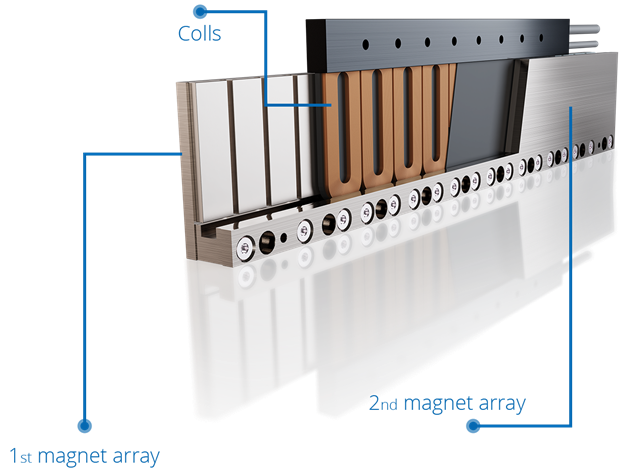

The coil unit is sandwiched between these two plates (see Figure 4) and, due to the absence of any magnetic material, it can provide a very accurate force level with an extremely low force ripple. Additionally, there is no attraction force between the coil unit and the magnet yoke which provides an extremely low stiffness orthogonal to the direction of movement.

Figure 4. “Phoenix” Ironless linear motor.

Ironless motors are therefore suitable for applications that require accuracies in the order of nanometers and/or where an accurate scanning motion (constant velocity) is needed.

Prodrive Technologies' Ironless motors, such as the Phoenix series (see Figure 4) are ideal for applications requiring extremely smooth and precise movements, for instance, in semiconductor manufacturing and metrology, DNA sequencing, or medical equipment.

Selecting the right motor type

Motor selection is the balance between motor size and temperature whilst fulfilling the motion and load requirements, and drive constraints.

Understanding the motion requirements

To avoid selecting a motor that is too large or too expensive for the application, it is important to determine the exact motion profile and how often this profile should be executed per unit of time.

The required force profile can be found from the actual motion profile, duty cycle, inertia (mass), friction, and damping. Consider incorporating the moving mass of the actuator as well (e.g. coil unit mass for a moving coil application). For an iron core motor, also consider the attraction force combined with the selected bearing system to determine the additional propulsion force that might be needed.

Both the peak force and continuous (or root-mean-square) force can be derived from this force profile. That helps you choose the proper motor size.

Defining the motor size

A coil unit has a relatively large thermal capacitance compared to electronic components. You can therefore take advantage of short-term variations in force without a significant impact on temperature.

Most coil units can either have temperature sensing (in the form of a PT1000 sensor) or temperature protection (in the form of a PTC), or both. This is important when the motor should be used close to the thermal limit and to avoid damaging the insulation system of the coils.

The cooling method, the ambient temperature, and the internal thermal resistance of the coil unit determine the maximum continuous losses a motor produces. These help you find the effective continuous force, which should be at least larger than the required continuous force derived from the motion profile.

Selecting the winding configuration (number of turns, parallel/series connection of coils)

The selection of the winding configuration balances voltage for current or vice versa. For example, an application with relatively low speeds should use a winding configuration with a higher force constant (higher number of turns or series connection of coils). This in turn reduces the required current level and allows you to use a motor drive with a lower current rating, which might reduce the overall system cost.

The Chiron and Phoenix motor lines offer four different types of winding configurations for most models, which lets you optimize the winding configuration to the application and minimize overall system cost.

Asking Prodrive Technologies to aid in motor selection using our Linear Motor Selection Tool

With the help of our proprietary motor selection tool, we can support you to optimize the motor selection for your specific applications, in finding the best technical and most economical solutions.

Selecting the appropriate linear motor can significantly influence system performance. Prodrive Technologies' broad portfolio lets you choose the perfect motor for your application. By understanding the strengths and weaknesses of Iron core and Ironless linear motors, you can make informed decisions that enhance the efficiency and effectiveness of your systems.

Figure 5. Linear motor selection tool.

Contact us if you have any questions or visit each product page for technical information.