Servo Drive

A servo drive, also known as a servo amplifier, is responsible for powering the servo motor in the system. The servo drive is a critical component in assessing the servo system's performance. Servo drives have several advantages over straight power amplifiers for automatic machining systems, including superior positioning, speed, and motion control.

Servo System Introduction

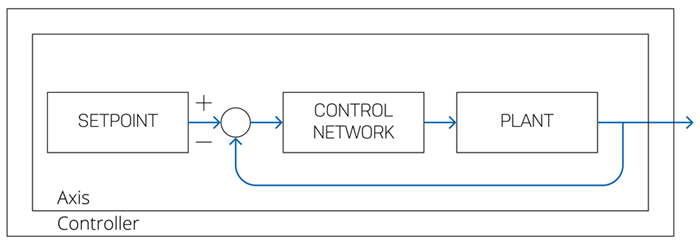

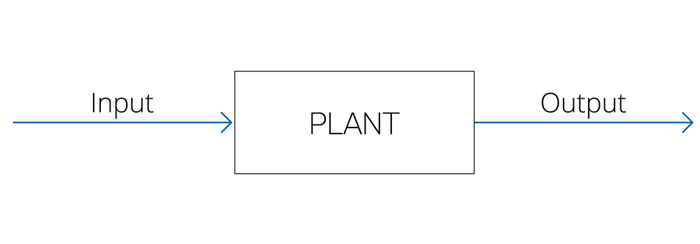

Servomechanisms are automated control systems that are used in a variety of applications such as robotics, industrial automation, and manufacturing. In motion applications, closed-loop systems with servo drives (See Fig. 1) provide greater reliability and precision than open-loop systems (See Fig. 2). Why? In contrast to open-loop systems, they use feedback to account for errors and system disturbances.

Figure 1. Closed loop system

Figure 2. Open loop system

Analog vs. Digital

Analog or digital inputs can be used to control servo drives. In essence, the servo drive is responsible to convert the controller's low-power command signals into high-power voltage and current for the motor. The servo drive can regulate and correctly coordinate the motor's desired position, speed, torque, and other parameters depending on the application.

Analog servo drives have been used in some motion control applications for many years. Analog drives do not require any processing time and are usually less costly than digital alternatives. In multi-axis applications, analog servo drives are manually configured and rely on a centralized controller.

However, digital servo drives can communicate using networks commands. Digital servo drives have much greater configuration and performance capabilities than analog devices. Modern servo drives provide superior diagnostic benefits due to their increased intelligence.

Today, the majority of the industry uses standardized Fieldbus networks for motion control. Industrial Ethernet networks have enabled manufacturers to operate in time-critical applications. While each network has its advantages, some products are designed for specific Fieldbus networks. Prodrive Technologies has developed drives, which can provide a wide range of communication interfaces including Ethernet, EtherCAT, RS485 (50MBps max), and CAN.

Closed Loop vs Open Loop

Servo drives use a feedback tracking device, most commonly an encoder, to transmit a signal back through its control loop or to the main controller to account for expected errors. The feedback device in a motion control system evaluates the error between the control input command and the actual feedback of the mechanism or the control shaft and adjusts the system behavior accordingly. Such feedback response represents a closed-loop system.

By making the required current or voltage modifications, the servo drive can regulate the difference between the actual and the desired motor position/velocity. This contrasts with an open-loop system, where there is not feedback device, in which the motor may spin at an incorrect RPM even though the position/velocity input command was similar to a closed-loop system.

This makes the use of a servo drive perfect for automatic systems that require position control. A servo drive can regulate a shaft to its desired position regardless of friction or other disturbances, whether it is just positioning a valve or moving with nanoscale accuracy.

Closed

Prodrive technologies offer several readily available drive options. These drives can be operated in stand-alone mode, used in combination with one of our motion controllers, or can be integrated within an existing motion control system. Prodrive Technologies offers several servo drive products in various configurations including, multi-motor outputs in one package, ultra-low output noise, high output linearity, and a wide range of connectivity options.