Advanced Camera Systems产品线涵盖了我们各种类型的摄像机系统。 我们开发先进的技术解决方案,在其中集成了从标准到客户特定成像仪的各种类型的传感器。 这是由于我们在光学,超高真空,精密机械,高速数据电子学和低噪声精密电子学方面的关键能力而实现的。 我们专注于内部批量生产的设计。 为了实现这一目标,我们的开发团队开发了高端无尘室生产流程,其中结合了诸如污染控制,成像仪放置,引线键合,干涉测量,显微镜和功能测试等知识。 当前正在进行研究,以实现高级摄像头的标准产品组合,以支持现有客户并为新市场创建起点

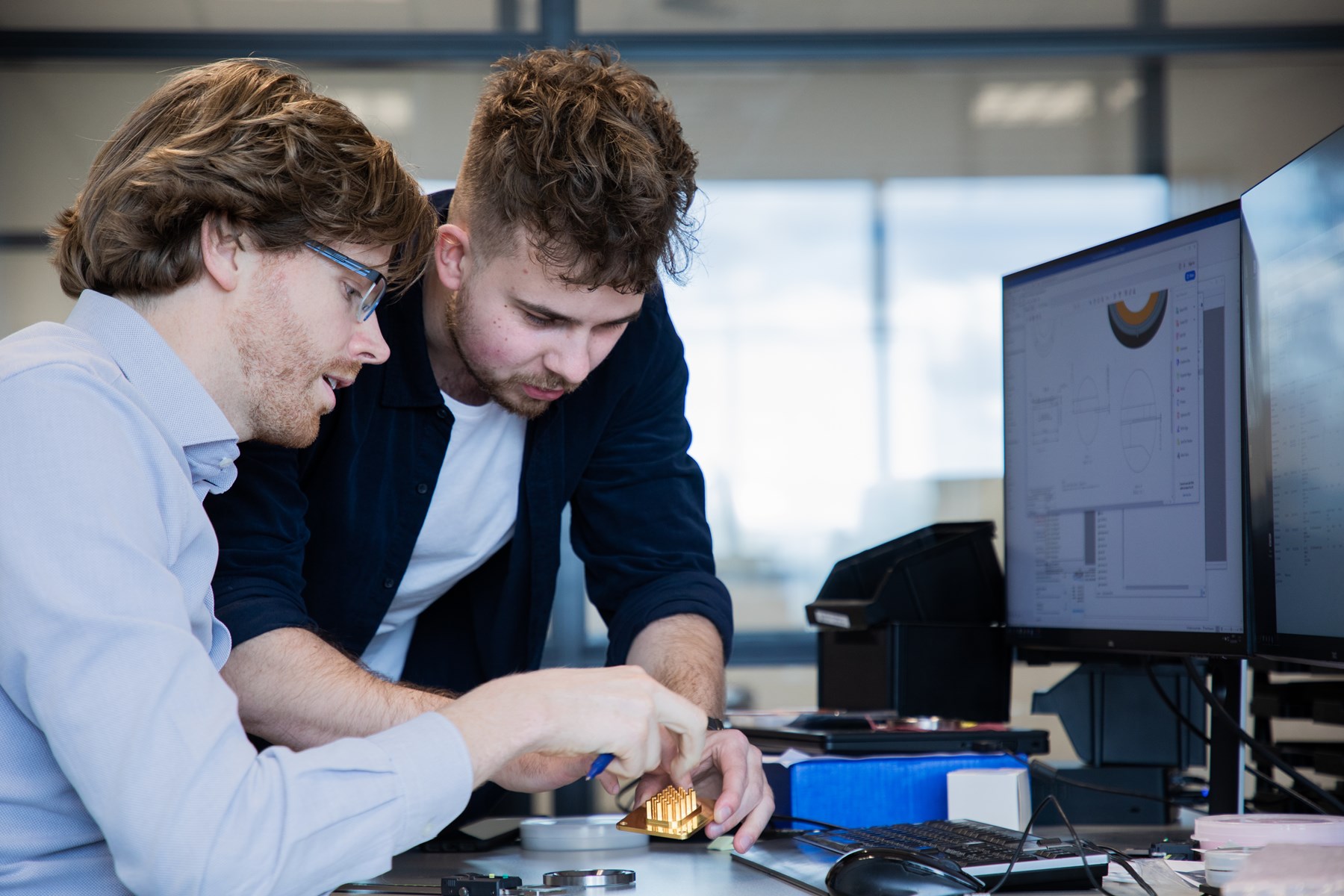

I started at Prodrive Technologies directly after receiving my master’s degree in applied physics, two years ago. I wanted to solve new technological challenges with creative colleagues, but I did not know exactly what role would suit me. Prodrive Technologies offered me the opportunity to become part of a small but ambitious design team, defining the next generation of custom power modules. Innovation in power module technology proves to be essential in the development of efficient electric cars. While bringing alive our new designs, I found myself developing the latest chip integration technologies in our cleanroom. Basically, I get to play with very expensive toys in order to bring about the newest technologies for making power modules.

A big benefit to Prodrive Technologies is that I can be mobile and grow in my field of interest, due to the extensive variety of competences we have available. In addition to power electronics, I am now involved in the design of exceptionally complex bonding processes for a high-end electron beam detector module. For this I surround myself with experts in the field, to combine and even expand multiple technologies beyond their current limits. The additional challenge here lies in designing a solution that is also suited for series production.

Inspiration is a reward, not a prerequisite

机械设计工程师 (1) profile

机械工程学士,工程学或硕士学位 熟悉3D机械设计软件-最好是西门子NX 系统设计,结构分析和设计原理方面的知识 与可制造性(DFM)设计密切相关

Pros and cons

自由地找到适合我并且我觉得最愉快的角色

在充满年轻热情的公司中工作

参与可能产生重大影响的产品开发

我们的流程开发部门不断成长。 如果我们有更多的才华横溢的过程开发人员,那么我们可以从事更迷人的项目。

I like to start my days early around 7 o'clock. With a cup of coffee I check my mailbox and prioritize my open actions. Later in the morning, I have meetings to align with my project teams, customers, supply chain, operations or other relevant connections. My days vary a lot from each other; some days I’m running from one meeting to another, some days I’m a day offsite at a customer or I check with my colleagues how we continue. I don’t manage people by telling them what to do. As a project manager I enable and support the project team and the rest of the organization to create the most amazing solutions for our customers. I mainly operate in the product line Advanced Cameras where we define, develop and maintain high-end camera products and their production processes. I am working at Prodrive Technologies for 11 years now, because Prodrive Technologies is continuously growing and exploring new technologies it is never boring here.

Grass doesn’t grow by pulling it, but by feeding its roots

Project manager profile

机械、电气、机电、工业工程或物理理学学士、工学学士或理学硕士

很强的沟通能力

能够进行概述

抗灾

多面手,而不是专家

决定性的

关系的方式

务实的

Pros and cons

每一天都不一样

创造非常酷的产品

与最有才华的人一起工作

该组织始终致力于最小化开销

我的项目中有很多交流界面,您永远无法满足所有人

These times are exciting. In the past months, I worked on the prototypes of a laser module, which is the sensing element in our fine particle sensor. It will be produced in series quite soon! I still find it hard to believe that the product I designed will be used in over a million cars worldwide. Before we get there, all the final tooling for production needs to be qualified.

One of the challenges we face is with our injection molded lenses. The prototype tool worked fine, but after replacement with the final tooling, the laser bundle is very distorted. This is a disaster, as our fully automated production line will be out of lenses soon!

We take maximum effort in finding the root cause. I run simulations to mimic the result in the lab, check functionality of the lens like focus and light output, and even decide to damage the good lenses to see what the impact is. I find that it is the coherent behavior of the laser light that is causing us trouble.

For our supplier, it is extremely difficult to check the performance of the lenses, as they do not have a laser setup that they can use. I decide to setup a tabletop optical qualification system, such that I can perform tests at their site.

At the supplier, we have a live process optimization session; the supplier tunes the injection molding process and I assemble the lenses to see which parameters work best. Afterwards, we compare the best and worst lenses, and manage to find our missing production tolerance! Now the supplier knows which parameter they should check to produce lenses for our laser system.

I love these technical discussions, which I also have at work with colleagues. It shows that by combining the talents and knowledge of multiple people, you can solve more difficult problems than you could have solved just by yourself. This is what I experience every day at Prodrive Technologies.

People with different knowledge and ideas make the best partners

机械设计工程师 (1) profile

机械工程学士,工程学或硕士学位 熟悉3D机械设计软件-最好是西门子NX 系统设计,结构分析和设计原理方面的知识 与可制造性(DFM)设计密切相关

Pros and cons

工作时间的灵活性。 好天气? 伙计们,明天见!

年轻的同事; 有时感觉好像我还没有大学毕业。 人们看到挑战而不是问题。

公司正在扩大。 这创建了一个似乎一切皆有可能的环境。 我的实验室设备精良,有太多项目可供我选择。

我每周仅工作4天,有时会导致错过操作。

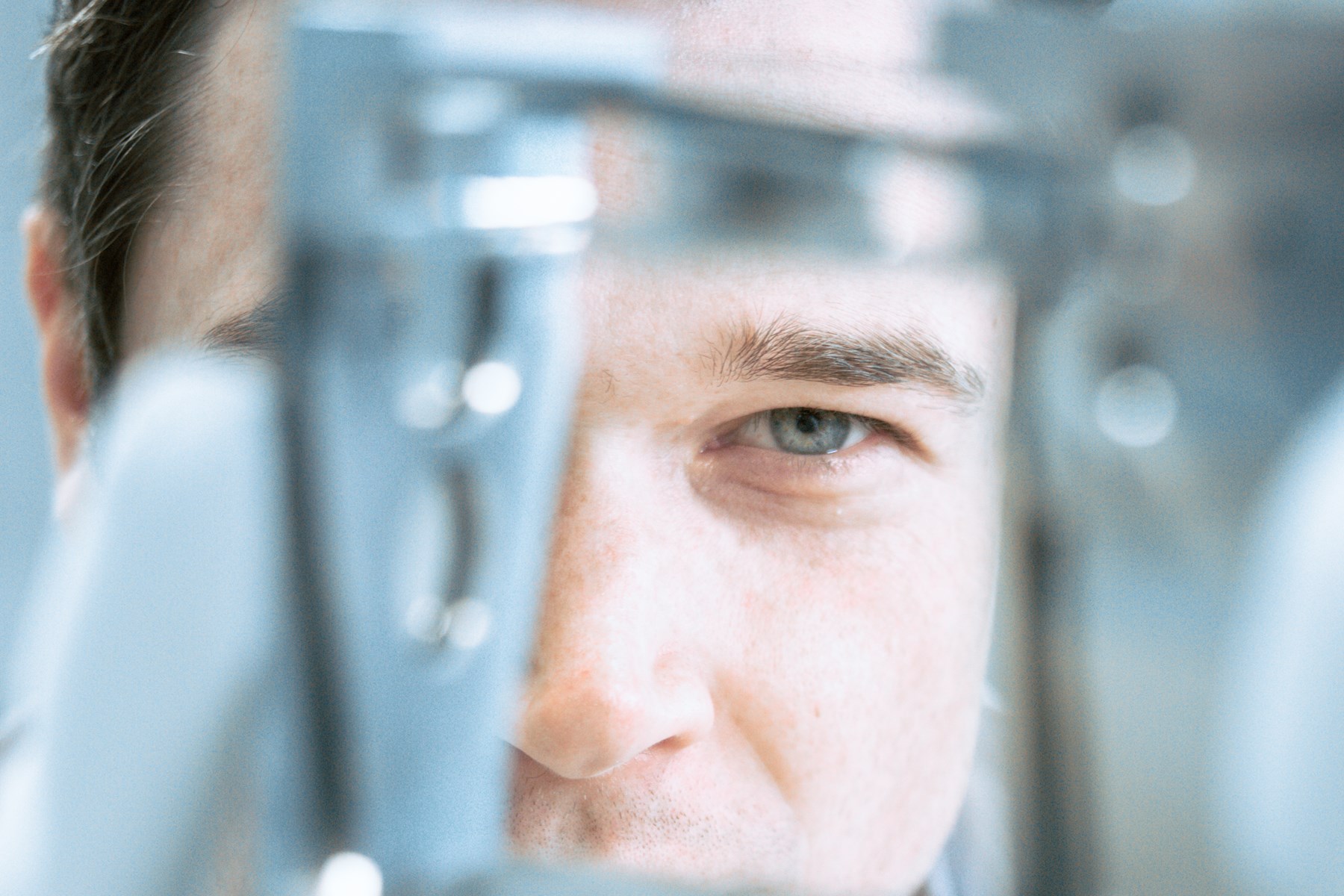

I am currently part of a project team that is designing an advanced camera system for electron microscopy. This system is used in an ultra-high vacuum environment, which requires the right material choices. The application shall have a linear guide operating at exceptional high speeds and it should be able to deal with extreme changes in temperature. My main challenge is to create a statically and thermally determined design, with low hysteresis effects. I tackled these challenges by applying various design principles and by designing thermal centers on the right locations.

Next to this project, I am mechanical system architect of a project focusing on the development of a mobile robot. The multidisciplinary project team consists of hardware, software and mechanical engineers. Together, we develop a conceptual design for a prototype to validate our concept. This mobile robot shall be able to automate part of our logistics. It contains various complex mechatronic components such as a lifting column, a telescopic bin picking platform and, of course, the powertrain. As a system architect, I am involved in all aspects of the design process; from close contact with our customer about system requirements and performance, to having in-depth discussions with our machining department about how to manufacture complex parts.

Just create cutting-edge technology and everything is possible!

Pros and cons

Working in an ambitious, young and self-steering team

High-Tech environment with very good facilities

Everything is done in-house

浦卓科技理念

Responsibility

You don’t just go to work, you feel responsible for your project

Flexible

You decide when, where and how much you want to work

Manufacturing

You like to think about manufacturability when designing

Initiative

You don’t sit and wait, you have a hands-on mentality

我们提供

- 为愿意承担项目全部责任的员工提供完美的工作环境

- 无限的成长机会和在不同项目中担任不同角色的自由

- 年轻且充满活力的企业文化

- 无限制的个人预算用于培训课程、课程或学习

- 我们全天候营业,提供午餐、晚餐和公司健身房

- 用你自己的个人发展计划创造你的未来

- iPhone、iPad和笔记本电脑等工具和设备

- 随时随地工作的灵活性

- 根据个人绩效涨薪

- 有机会成为公司的股东和企业家

- 根据您在浦卓的实际工作天数提供差旅津贴

- 利润分红

申请步骤

- 我们会查看你的申请

- 能力倾向测验

- 面试

- offer沟通