我们的目标是一个全自动铣床领域。这意味着机器人将托盘和产品放入或取出机器

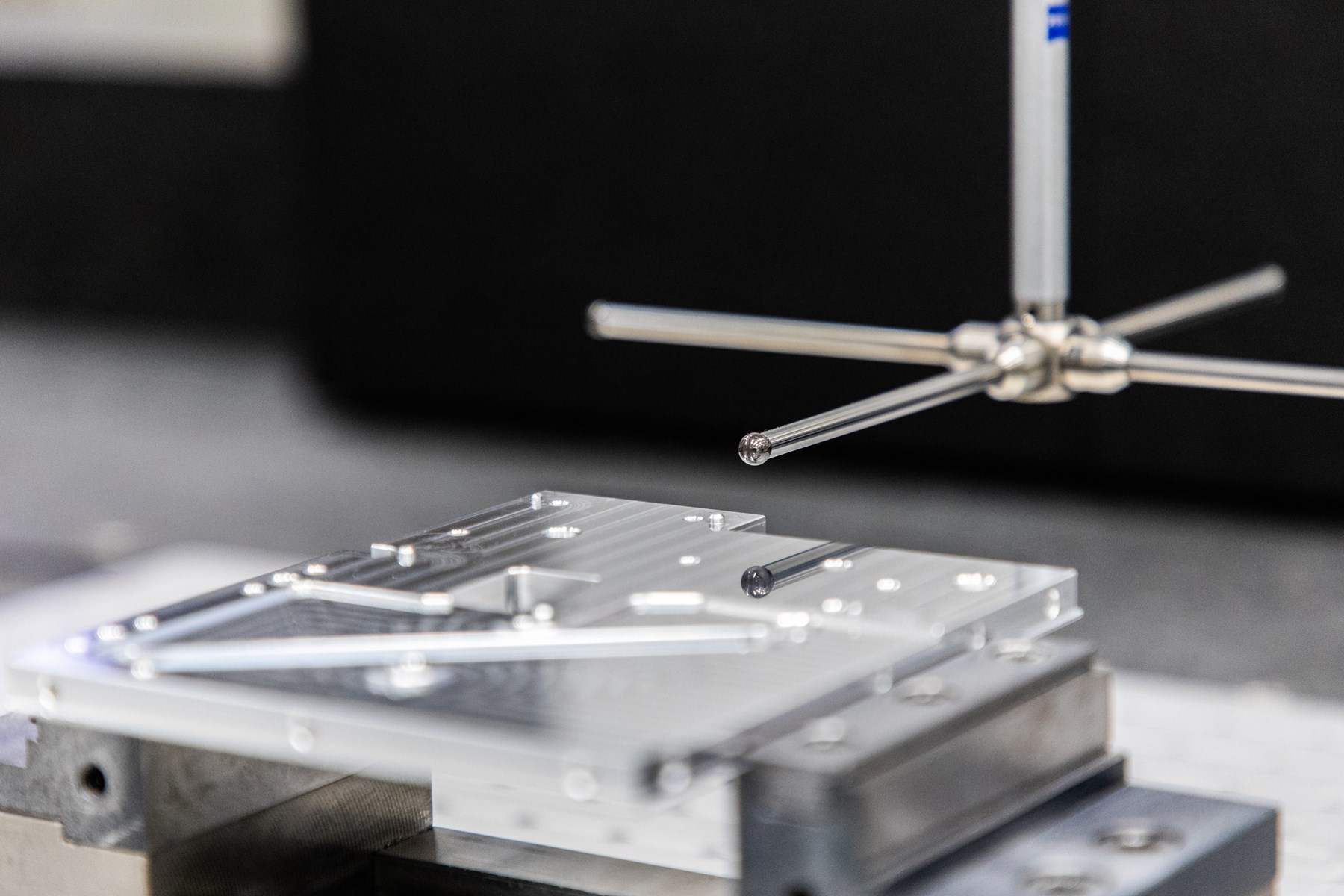

牧野D500、Matsuura Lumex Avance-25、Hermle C60和Datron MLCube让不可能变为可能。高精度和大的工作空间提供了几乎无限的铣削可能性,这是非常有用的在我们的行业。铣削加工在检验站完成。产品在坐标测量机上进行测试,精度为0.001毫米。我们的一些产品可以挽救生命,所以不能粗心大意。

我们的目标是一个全自动铣床领域。这意味着机器人将托盘和产品放入或取出机器

牧野D500、Matsuura Lumex Avance-25、Hermle C60和Datron MLCube让不可能变为可能。高精度和大的工作空间提供了几乎无限的铣削可能性,这是非常有用的在我们的行业。铣削加工在检验站完成。产品在坐标测量机上进行测试,精度为0.001毫米。我们的一些产品可以挽救生命,所以不能粗心大意。

Each evening I wait until I get the shift transfer from my colleagues. This gives us insight in our progress and information about possible complications.

Some people start their day with coffee, but I prefer to train hard in our company gym. It warms up my mind and body for work.

According to the planning and information from the shift before, I begin preparing the tools and machines together with Sebastian and Rick. Our job is not light and simple, but the technologies we use makes it much easier. Everyone who work with machines regularly is impressed by our department. Like I always say, “It’s better to drive a Bentley than a Fiat, right?”.

Currently half of our team is focused on creating clamping systems for new milling machines and molds for the injection molding department. We find solutions ourselves for many production problems and improve our processes with new technologies that make things simpler. I’m never bored at work and I learned many things so far, but it’s just a small fraction of what I can still learn at Prodrive Technologies.

It’s better to drive a Bentley than a Fiat, right?

工作时的心态

对技术的热情

两班制

完美的工作环境(顶级机器,主要组织)

我曾经合作过的最友好,最有帮助的团队

发展机会

公司健身房

One year ago, I decided to work as CAD-CAM engineer besides my work as mechanical engineer. As CAD-CAM engineer I’m involved in the realization of mill parts. It starts with programming the CNC code using advanced CAD-CAM software and setting up the right process. After programming, I verify my program on the newest 5 axis milling machine. Afterwards, I inspect my milled product with high quality coordinate measuring machines and check if all specifications are reached. After verification my program is ready to start automated series production.

Through my experience as mechanical designer and CAD-CAM engineer I can help other mechanical designers with DFM (design for machining). I try to get designs to a higher level in the field of manufacturability and costs. A low-cost product starts with a design that satisfies the DFM guidelines. Together with designers I discuss the complex precision products after milling and measuring to optimize quality and manufacturability.

Besides, I’m currently also working to automate the generation of CAD-CAM programs. Together with other CAD-CAM engineers we determine the specifications of the software and we test the software to give feedback. Step by step we create our own CAD-CAM automation. The combination of CAD-CAM engineering and software development within Prodrive Technologies creates the best software that fits our requirements.

The realization of new complex products and the optimization of our milling process is one of the nicest things of my job. This drives me to create the milling factory of the future.

Our in-house production facilities create the opportunity to be involved from design to realization

使用最新最好的机器

灵活的工作时间

很棒的午餐和晚餐

从第一天起的责任

好的同事和工作环境

将我的CAD-CAM工程师和机械设计工程师的工作结合在一起的时间很少。 两者都太好了,无法选择其中之一。

In 2017 I started my internship at Prodrive Technologies. At that moment I was triggered by the company because it’s unique strategy that Prodrive Technologies develops and manufactures their own products in-house. The project was about validation of mechanical products via the coordinate measuring machine, for which they was not yet a mature process developed. This was a project within the machining department. I continued to work part-time after finishing the project besides finishing my university. Later on, I successfully finished my graduation internship at the development department. It was a nice experience, but I felt more comfortable by working at the manufacturing environment; the semi-office job with the hands-on mentality.

After finishing my mechanical engineering bachelor, I got the opportunity to start as a process engineer at mechanics manufacturing and became responsible for improving our metrology and verification process of mechanical parts. Besides that, I started developing a new production process; turning (and multitasking). For me it feels great that I get such big responsibilities in the beginning of my career. This enables me to optimally develop myself. As a result of this, I play a key role in further improving metrology and expand the competence to other manufacturing processes, such as magnetics and system assembly. I am really proud of this achievement!

Finally, I want to say that it’s amazing to work daily with state of the art machinery, manufacture high-end precision parts, and be of significant value to exceed world class manufacturing. Not forget to mention that working with such cooperative and talented colleagues who have similar interests and ambitions is extra motivating.

I’m currently part of a team which is creating a new era in the accuracy of our erosion-based machining processes. This process is – quite literally – cutting the edges of technology and is able to produce products up to sub-micron accuracies, thus giving shape to the complex and high-end designs of our portfolio.

In my role as Process Engineer, I’m involved in many aspects of the production process, from pinpointing possible improvements with our process team about for instance the maintenance of our machines or checking with our mechanical designers how we can complement in the cooperation between design and production, staying ahead of upcoming requirements already.

Controlling, qualifying and analyzing performance goes hand in hand with brainstorming about improvement opportunities for the production processes. Whether we need new tools, machinery, or custom software to realize our goals, as a process-team we define the requirements and match them with possible competences within Prodrive, or with external suppliers to turn the process up a notch every day.

Making new ideas reality is what brings evolution, just to give you an idea.

The drive, created by the combination of trust, responsibility and freedom to create a one[1]of-a-kind production-process, ready to push the boundaries of accuracy and reliability every day

Five years ago, I started working at Prodrive as a part-time Technician on the weekends. The moment I walked in on my first day I already felt comfortable. I was welcomed by everyone with enthusiasm and saw a sea of opportunities. After some time, I became a Support Engineer. This new role broadened my knowledge. I learned to dive deeper into the machines and help my colleagues to solve problems. One of my favorite things about working at Prodrive is the variety — no two days are the same. Every day offers its challenges, and you never know where each day is going to take you.

After one year as a Support Engineer, I started working as a full-time Work Preparation Engineer. I learned to make programs using our CAD-CAM software. When a program is finished it needs to be verified on our 5-axis CNC machines. After milling the first part, I measure all the dimensions to make sure the part is within tolerance. The products with high tolerances must be measured on our coordinate measuring machine, for which we must create a program.

The first thing I do when I start my day at Prodrive is walk around all our CNC milling machines. The reason I do this is to make sure that everything is still up and running. If a machine is down, I will try to make it operational again. During the day I improve old programs and help technicians when they have technical problems on a machine.

The best thing about my job is that I continue to learn every day. From my colleagues and from the projects I work on.

MBO+, BSc or BEng diploma in Verspaning, Werktuigbouwkunde of Mechatronica.

Bekend met het voorbereiden en afstellen van CNC machines.

Kent alle ins en outs van de verspaning.

Bekend met CAD/CAM software – waarbij voorkeur naar Siemens NX.

Skills om de technische tekening te vertalen naar een eindproduct.

Praktische manier van denken en hands-on mentaliteit. Goede communicatie vaardigheden.

Affiniteit met het werken in de metaal

Working with new machines

Flexible working hours

A good working environment

Diverse working activities

You don’t just go to work, you feel responsible for your project

You decide when, where and how much you want to work

You like to think about manufacturability when designing

You don’t sit and wait, you have a hands-on mentality