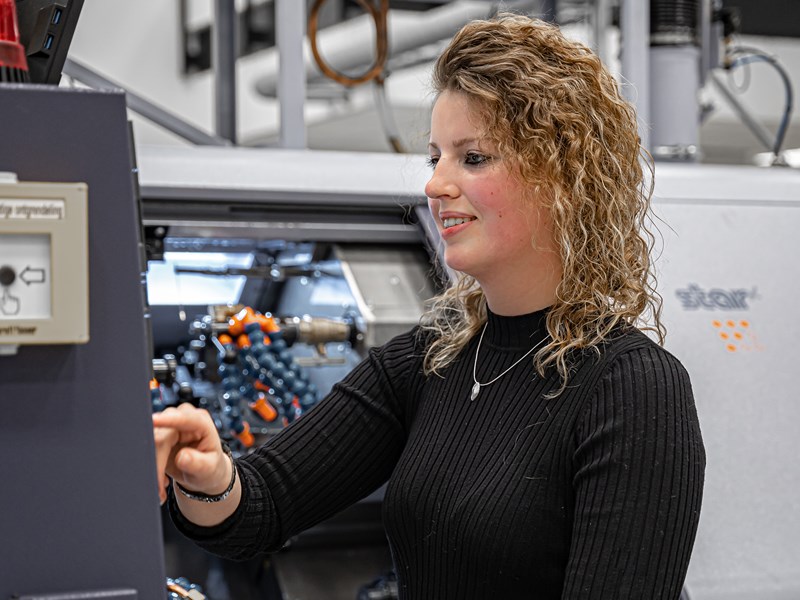

We are aiming for a fully automatic milling machine area. This means that a robot is placing and taking pallets and product in and out of the machine.

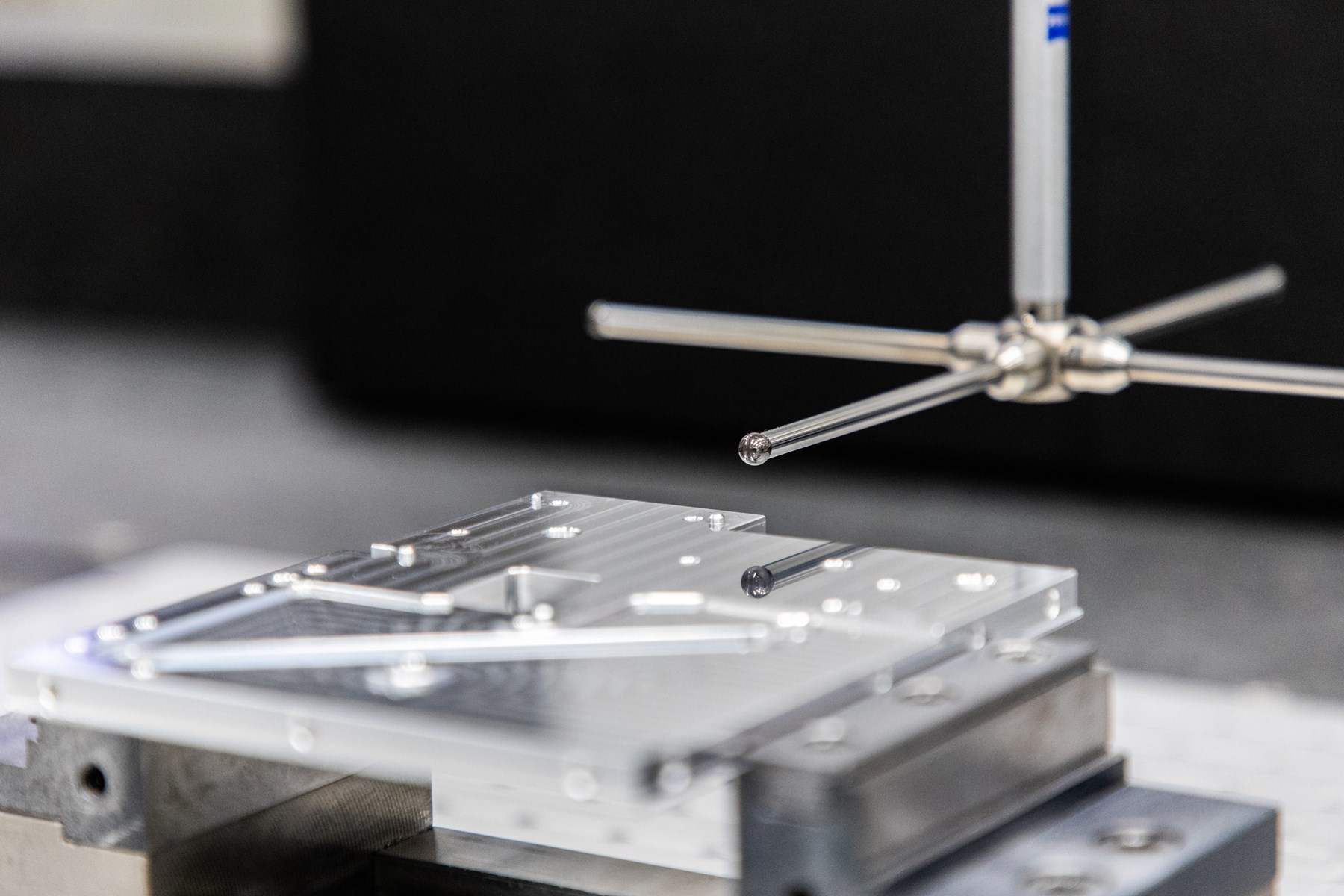

The Makino D500, Matsuura Lumex Avance-25, Hermle C60 and Datron MLCube machines make impossible things possible. High accuracy and large working space gives almost unlimited milling possibilities, which is very useful in our industry. The milling process is finished at the inspection station. Products are tested on a coordinate measuring machine with an accuracy of 0.001 mm. Some of our products save lives, so there is no room for carelessness.