The Advanced Camera Systems product line covers our various types of camera systems. We develop advanced technology solutions in which we integrate different types of sensors ranging from standard to customer specific imagers. This is enabled by our key competences in optics, ultra-high vacuum, precision mechanics, high speed data electronics, and low noise precision electronics. We design with focus on in-house series production. To achieve this, high-end cleanroom production processes are developed within our development teams, where knowledge such as contamination control, imager placement, wire bonding, interferometry, microscopy, and functional testing is combined. Research is currently performed towards the realization of a standard product portfolio of advanced cameras that support existing customers and to create a starting point for new markets.

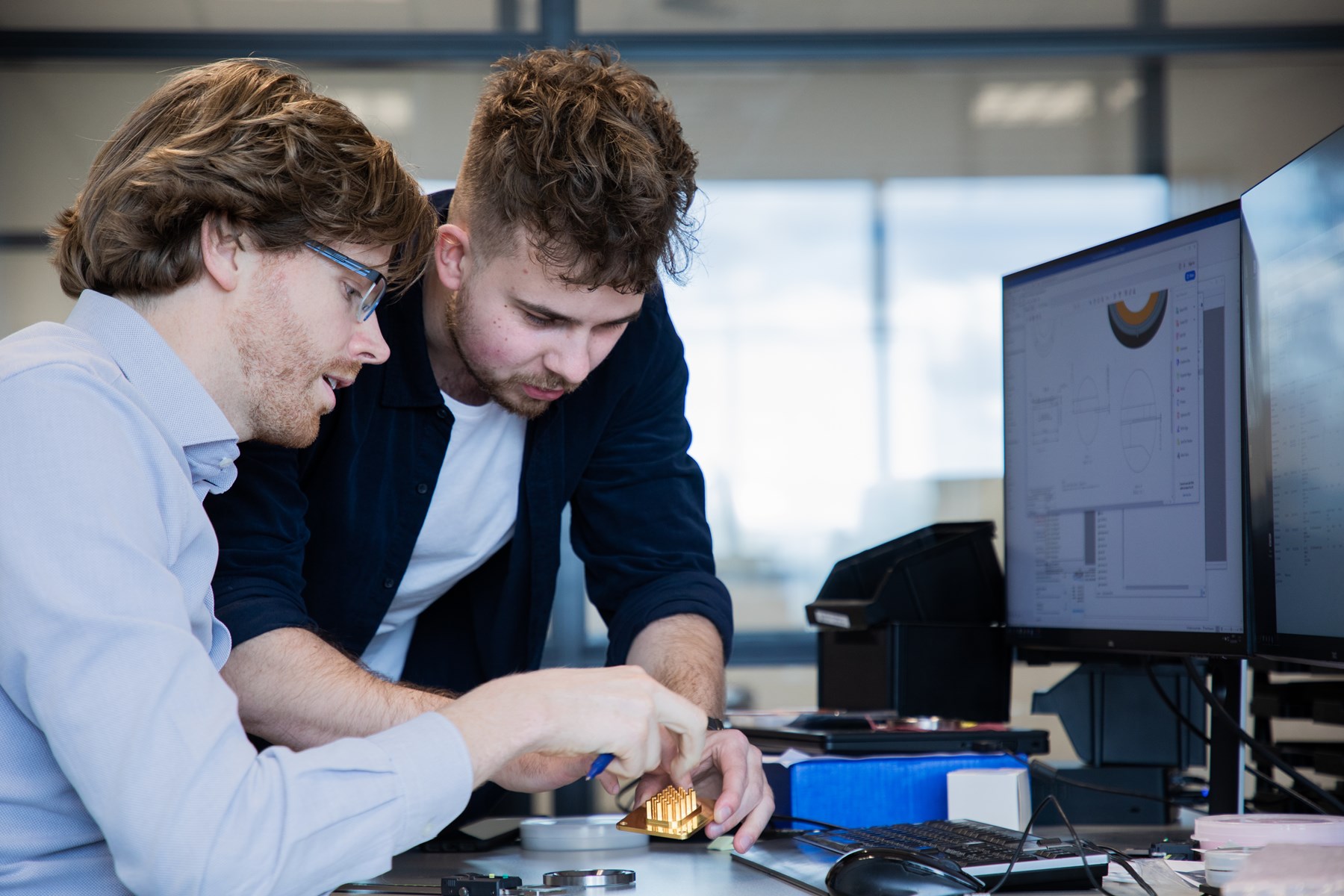

I started at Prodrive Technologies directly after receiving my master’s degree in applied physics, two years ago. I wanted to solve new technological challenges with creative colleagues, but I did not know exactly what role would suit me. Prodrive Technologies offered me the opportunity to become part of a small but ambitious design team, defining the next generation of custom power modules. Innovation in power module technology proves to be essential in the development of efficient electric cars. While bringing alive our new designs, I found myself developing the latest chip integration technologies in our cleanroom. Basically, I get to play with very expensive toys in order to bring about the newest technologies for making power modules.

A big benefit to Prodrive Technologies is that I can be mobile and grow in my field of interest, due to the extensive variety of competences we have available. In addition to power electronics, I am now involved in the design of exceptionally complex bonding processes for a high-end electron beam detector module. For this I surround myself with experts in the field, to combine and even expand multiple technologies beyond their current limits. The additional challenge here lies in designing a solution that is also suited for series production.

Inspiration is a reward, not a prerequisite

Pros and cons

Freedom to find the role that suits me and that I find most enjoyable

Working within a company filled with young, passionate people

Being involved in the development of products that may have a meaningful impact

We’re continuously experiencing growth in our process development department. If we had a larger number of talented process developers, we could engage in even more fascinating projects.

I like to start my days early around 7 o'clock. With a cup of coffee I check my mailbox and prioritize my open actions. Later in the morning, I have meetings to align with my project teams, customers, supply chain, operations or other relevant connections. My days vary a lot from each other; some days I’m running from one meeting to another, some days I’m a day offsite at a customer or I check with my colleagues how we continue. I don’t manage people by telling them what to do. As a project manager I enable and support the project team and the rest of the organization to create the most amazing solutions for our customers. I mainly operate in the product line Advanced Cameras where we define, develop and maintain high-end camera products and their production processes. I am working at Prodrive Technologies for 11 years now, because Prodrive Technologies is continuously growing and exploring new technologies it is never boring here.

Grass doesn’t grow by pulling it, but by feeding its roots

Project Manager - Embedded Computing Systems profile

BSc, BEng, or MSc in Mechanical, Electrical, Mechatronic, Industrial Engineering, or Physics.

Strong understanding of embedded computing systems and technologies.

Excellent leadership, interpersonal, and problem-solving skills.

Strong organizational and time-management abilities.

Ability to thrive in a dynamic and fast-paced environment.

Being decisive, a relationship-builder, and pragmatic.

Authorized to work in the US (for Boston/Canton Branch applicants only)

Pros and cons

Every day is different

Creating very cool products

Working with the most talented people

The organization is always focusing on minimizing overhead

I have a lot of communication interfaces in my projects and you can never satisfy everyone

These times are exciting. In the past months, I worked on the prototypes of a laser module, which is the sensing element in our fine particle sensor. It will be produced in series quite soon! I still find it hard to believe that the product I designed will be used in over a million cars worldwide. Before we get there, all the final tooling for production needs to be qualified.

One of the challenges we face is with our injection molded lenses. The prototype tool worked fine, but after replacement with the final tooling, the laser bundle is very distorted. This is a disaster, as our fully automated production line will be out of lenses soon!

We take maximum effort in finding the root cause. I run simulations to mimic the result in the lab, check functionality of the lens like focus and light output, and even decide to damage the good lenses to see what the impact is. I find that it is the coherent behavior of the laser light that is causing us trouble.

For our supplier, it is extremely difficult to check the performance of the lenses, as they do not have a laser setup that they can use. I decide to setup a tabletop optical qualification system, such that I can perform tests at their site.

At the supplier, we have a live process optimization session; the supplier tunes the injection molding process and I assemble the lenses to see which parameters work best. Afterwards, we compare the best and worst lenses, and manage to find our missing production tolerance! Now the supplier knows which parameter they should check to produce lenses for our laser system.

I love these technical discussions, which I also have at work with colleagues. It shows that by combining the talents and knowledge of multiple people, you can solve more difficult problems than you could have solved just by yourself. This is what I experience every day at Prodrive Technologies.

People with different knowledge and ideas make the best partners

Pros and cons

Flexibility of working hours. Good weather? See you tomorrow, guys!

Young colleagues; sometimes it feels like I haven’t left university. People see challenges instead of problems.

The company is expanding. This creates an environment where everything seems possible. My lab is amazingly equipped and there are so many projects that I can pick the ones I like.

I work only 4 days a week and that sometimes results in missing the action.

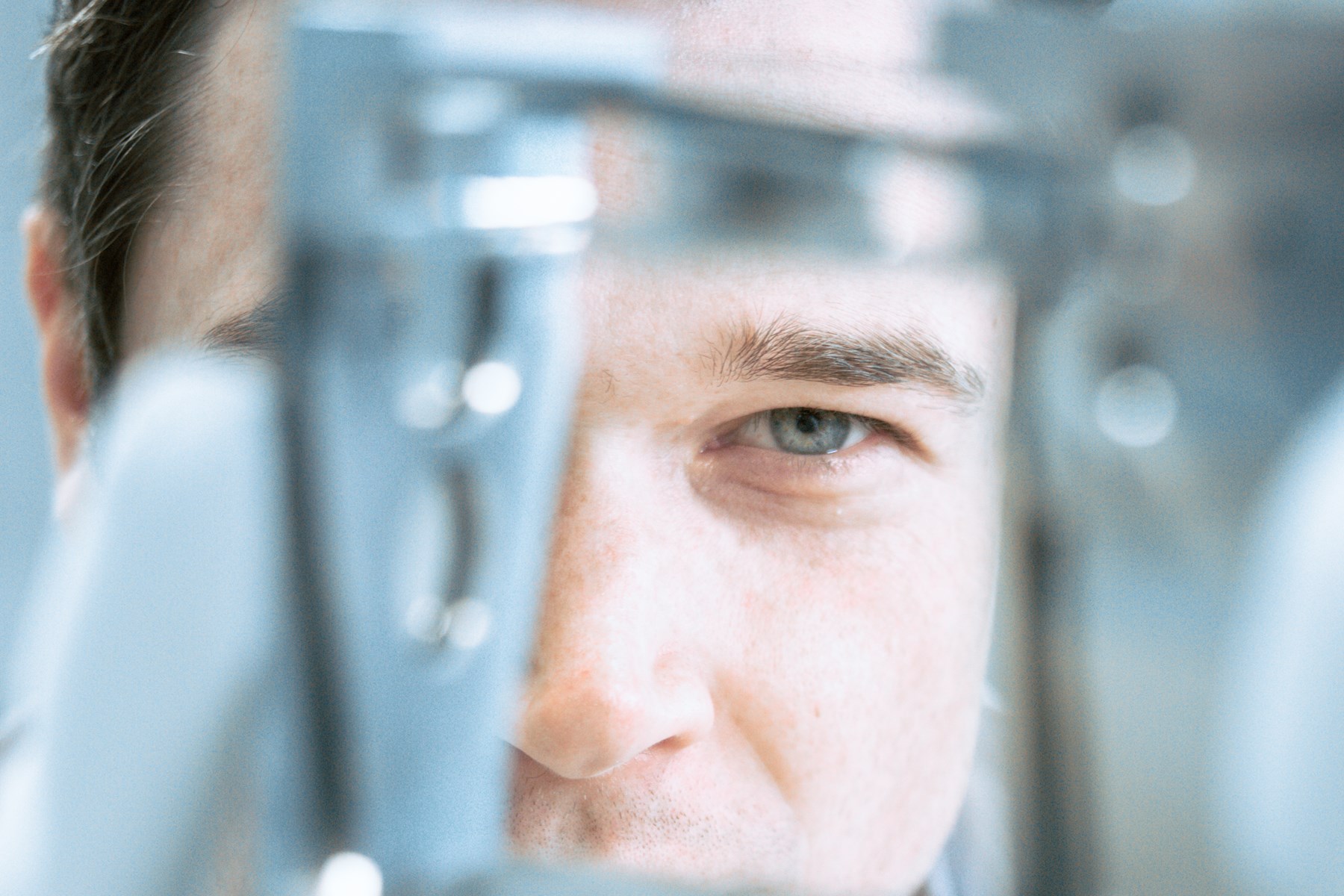

I am currently part of a project team that is designing an advanced camera system for electron microscopy. This system is used in an ultra-high vacuum environment, which requires the right material choices. The application shall have a linear guide operating at exceptional high speeds and it should be able to deal with extreme changes in temperature. My main challenge is to create a statically and thermally determined design, with low hysteresis effects. I tackled these challenges by applying various design principles and by designing thermal centers on the right locations.

Next to this project, I am mechanical system architect of a project focusing on the development of a mobile robot. The multidisciplinary project team consists of hardware, software and mechanical engineers. Together, we develop a conceptual design for a prototype to validate our concept. This mobile robot shall be able to automate part of our logistics. It contains various complex mechatronic components such as a lifting column, a telescopic bin picking platform and, of course, the powertrain. As a system architect, I am involved in all aspects of the design process; from close contact with our customer about system requirements and performance, to having in-depth discussions with our machining department about how to manufacture complex parts.

Just create cutting-edge technology and everything is possible!

Pros and cons

Working in an ambitious, young and self-steering team

High-Tech environment with very good facilities

Everything is done in-house

The Prodrive Technologies Mindset

Responsibility

You don’t just go to work, you feel responsible for your project

Flexible

You decide when, where and how much you want to work

Manufacturing

You like to think about manufacturability when designing

Initiative

You don’t sit and wait, you have a hands-on mentality

What we offer

- Perfect environment for those eager to develop themselves and take full responsibility for a project.

- Many opportunities for personal and professional development, along with the flexibility to explore diverse roles across various projects.

- A young and dynamic culture which stimulates innovative thinking and taking initiatives.

- Personal budget just for you to learn new things. Your growth is our priority.

- Flexibility of a 24/7 work environment with provided lunch, dinner, and access to our company gym.

- Personalized development plan to craft your future.

- You will receive essential tools if these are necessary to perform your job (i.e. iPhone and laptop).

- On-campus sports facilities enable you to incorporate exercise seamlessly into your work routine.

- A performance-driven salary that grows with your accomplishments.

- Unlock the opportunity to become a shareholder and entrepreneur within the company.

- Travel allowance based on the days you are actually at Prodrive Technologies.

- Work-life balance with at least 33 vacation days per year.

- Access a retirement plan.

Application steps

- Your journey with us starts with a swift review of your application by one of our recruiters.

- In some cases, if we see a potential fit, you will receive an exclusive link to our online aptitude test to assess if you’re up for the challenge.

- We will schedule a personal interview not only to determine if your skills match the job, but also to see if there is a spark between you and Prodrive Technologies.

- To complete the application journey we will send you a suitable offer and once you sign, we can welcome you to the Prodrive Technologies family.