Test automation is working on the Prodrive Technologies goal of a Lights Out Factory. The electronic test system supports that goal by providing test equipment with a uniform interface and form factor, so manufacturing lines can easily be configured for the product’s needs. The test equipment includes power supplies, programming modules and measurement tools, all with a common interface to the test system. Combined with other projects, such as an in-house developed Manufacturing Execution System (MES) and Automated Guided Vehicle (AGV), we are realizing the goal of a Lights Out Factory.

The bulk of my work is to support colleagues who automate product tests which will be used in the production line. For example, I’m asked to extend one of our flash programming libraries to support a new device. I look up the library’s original target device’s manual, and the new device’s manual, and find out how compatible they are. It turns out all three layers of the software stack need some work. Later this week I’ll sit down with the FPGA engineer, and then with our project architect, to propose new software interfaces between the layers.

Another example is a test developer who came to me with a question: they received an error message while using one of our libraries, and don’t know what to do about it. Neither do I, so I look through the code to figure out what can trigger that message. I find the culprit, tell the user how to fix it, and add a task to our kanban board to improve the message so the next user doesn’t have to ask.

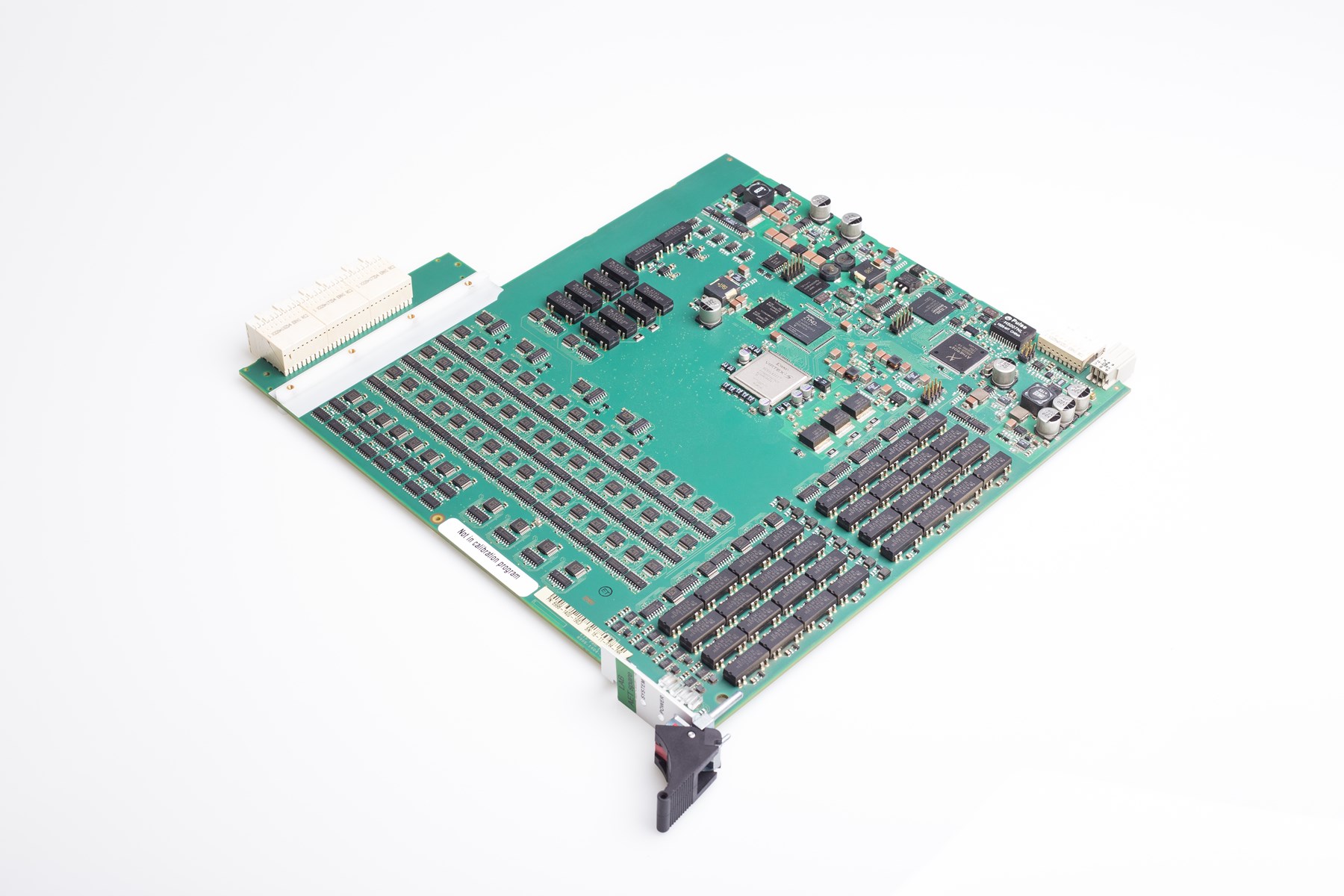

Our electronic test system provides independent hardware modules which are used to test and program products in our own production line. For the test developers we provide software and a set of standardized interfaces to talk to the ETS modules, which can be as granular as setting a specific signal to 1.6 volt, or as high-level as writing firmware to a flash chip. Together with the test development team, we ensure the reliability of these processes so the lights at the factory can stay out.

Turning bugs into features

Pros and cons

Many different sub-projects, so I’m rarely bored.

Customers are right across the hall.

Everything from analog signal analysis to .NET desktop applications.

My career at Prodrive Technologies started quite some years ago during my university of applied sciences (HBO) studies. That time I wanted to get more hands on experience to dive into electronics and software. I have started my career as Service Engineer focusing on production service. After feeling confident in this role and having interest in test creation itself I have switched to the Test Development cluster. What is exiting about this is I do determine tests to be performed on a product and communicate with customer about test coverage. Thinking globally about the product is always a challenge and possibility to learn.

Test engineer is an unique engineer who has knowledge in hardware and in software. The combination of both competences makes it work.

Every day at Prodrive is different and I cannot really call Prodrive as my “work” place, better fits “hobby”. When I come to the office I am happy get another challenge and solve it. This usually makes my day.

Prodrive is not work, but a hobby.

Embedded Electrical Engineer profile

Bachelor's or Master's degree in Electrical Engineering, Computer Engineering, or a related field.

Proven experience in embedded systems design and development, with a focus on hardware and software integration.

Proficiency in embedded software development languages and tools, such as C/C++ and Python, and microcontroller programming.

Strong understanding of electrical engineering principles, including analog and digital circuit design, PCB layout, and signal processing.

Experience with system-level thinking and the ability to translate requirements into practical, scalable solutions.

Excellent problem-solving skills and the ability to work effectively in a collaborative team environment.

Self-motivated with a proactive approach to learning and professional development.

Excellent communication skills and the ability to articulate technical concepts clearly and concisely.

Pros and cons

Healthy environment at Prodrive is stimulating high efficiency

Prodrive offers amazing fitness facilities with delicious lunch and dinners

Possibility to communicate with other engineers on the same level makes learning process smooth and not stressful

I like to start my workday early with a cup of coffee and making a plan of the workday ahead.

Every day is a different day. Today, in the morning my task list can consist of analyzing a product design and give feedback to my colleagues in the design team to optimize the design on testability. While in the afternoon, I am busy defining a test strategy. Currently I am making a test strategy for our Gradient Amplifier. I like the challenge to solve this puzzle to find an optimum test flow by taking into account the quality target, test time, usage of standard tooling, fitting in our manufacturing processes and customer requirements.

Tomorrow will be completely different. I will be busy with designing and implementing a test and verifying and debugging test hardware and software in the lab.

Solving challenging problems and working in a team of talented people gives me energy.

Embedded Electrical Engineer profile

Bachelor's or Master's degree in Electrical Engineering, Computer Engineering, or a related field.

Proven experience in embedded systems design and development, with a focus on hardware and software integration.

Proficiency in embedded software development languages and tools, such as C/C++ and Python, and microcontroller programming.

Strong understanding of electrical engineering principles, including analog and digital circuit design, PCB layout, and signal processing.

Experience with system-level thinking and the ability to translate requirements into practical, scalable solutions.

Excellent problem-solving skills and the ability to work effectively in a collaborative team environment.

Self-motivated with a proactive approach to learning and professional development.

Excellent communication skills and the ability to articulate technical concepts clearly and concisely.

Pros and cons

Challenging projects

Diversity in projects and customers

Flexibility of working hours

Working together with talented people

Losing track of time while working on challenges projects

My adventure at Prodrive Technologies started with my graduation project. I started with a nice challenging project: an AET (Automated Electrical Test) had to be developed for a new gradient amplifier (part of an MRI system). My part of this project was to design and develop the AET for the control board of the MRI gradient amplifier. The control board is considered one of the most complex parts of a machine to test with AET.

In order to design and develop the AET, I first had to understand the technology of this machine. For this I could always get advice from my colleagues. They were happy to make time to answer all kinds of questions.

After my research of what needed to be tested and how this could be done automatically, I made a design specification document (DSD) for the gradient amplifier. In this document is specified why and how test shall be done.

After I designed and developed the schematic and the software, the mechanical and electrical parts were manufactured by our production facilities.

In the end I have designed, developed, programmed and manufactured a test for the gradient amplifier control board. It was interesting to learn so much about such an ambitious project. The Gradient amplifier (of an MRI) controls very high currents and very high voltages at great precision. There is a lot of technology involved, which requires a lot of knowledge of test designers. I learnt a lot from my colleagues working on this project.

After my graduation I got offered a job as Test Developer. It is great that many of my fellow students who graduated at the same time, continued to work at Prodrive, some even at the same project as I. Hopefully we can make this project even more successful this way.

It was interesting to learn so much about such an ambitious project

Embedded Electrical Engineer profile

Bachelor's or Master's degree in Electrical Engineering, Computer Engineering, or a related field.

Proven experience in embedded systems design and development, with a focus on hardware and software integration.

Proficiency in embedded software development languages and tools, such as C/C++ and Python, and microcontroller programming.

Strong understanding of electrical engineering principles, including analog and digital circuit design, PCB layout, and signal processing.

Experience with system-level thinking and the ability to translate requirements into practical, scalable solutions.

Excellent problem-solving skills and the ability to work effectively in a collaborative team environment.

Self-motivated with a proactive approach to learning and professional development.

Excellent communication skills and the ability to articulate technical concepts clearly and concisely.

Pros and cons

There were 7 students working at Prodrive from my university. We could discuss our different projects with each other, which was nice

The free lunch and dinner

Good internship allowance

Would be nice if Friday afternoon drinks are organized more frequently

At Prodrive we have built our own test machine to test the assembled PCB's that roll off the production line. This machine is called the AET and it has many different components and sub-projects, but the project of which I am the architect generally handles low level software and APIs for our production test developers.

In the morning I usually start with a meeting to discuss a new software interface that was proposed by one of the engineers in the team. We check if all the functionality is there and if any improvements are to be made.

After the review I will start working on a new application that helps test developers handle continuous integration. Where I usually use C & C++, I’m actually learning C# to make this application. This is what is so nice about Prodrive there are no defined roles, if you are an application engineer who wants to do an embedded project that is possible, and of course in my case the other way around.

At the end of the day I am called by the HR department during the interview of a potential candidate and they ask if I can conduct the technical part of the interview. So maybe when you apply for a job, we will get to meet each other during your interview.

The best way to predict the future is to invent it

Pros and cons

A lot of teamwork

Learning new things each day

Flexible working hours

Free lunch and dinner

Within Prodrive we develop our own automatic test machines. These machines, called AETs, are used in our factory to test products in various stages of production, from PCBs right out of the oven to large fully assembled products. There are a lot of projects related to the AET and Test Automation, my main responsibility is software architect of the software used to control the hardware inside the AET machines.

We are currently in the design phase for a new inline test machine. Subassemblies are still being designed. My work consists mainly of reviewing design choices in mechanics and electronics to ensure smooth integration with software later on. I am also working on the high level software design that will tie the control of all the modules in the machine together.

We have a workstation configuration (standalone setup for larger products) which is currently already being used in our factory. For this machine I am adding features requested by the users or fixing issues if they are found. As these machines are used in production and their number is growing fast, rolling out updates always comes with a risk. Aside from ensuring the quality of the update content I have to consider scenarios related with the update itself. This is where my experience as NCO in the army reserves really comes in handy; strategizing the rollout for a complex update and preparing for all sorts of scenarios.

Not too long ago I have discovered two related bugs in the firmware upgrade mechanism of one of the modules which prevented it from being updated more than once and could brick the board if shutdown at the wrong time. I designed an update package that would fix the issue but that required overwriting critical parts in memory like the bootloader. This was a one-shot opportunity which if failed required manually replacing the board in each machine. Implementation took 2 days, qualification and testing every scenario I could think of 2 weeks and the rollout… 2 minutes that felt like an hour. It was an exciting time seeing the boards go down and waiting that crucial, excruciating, 30 seconds after which the boards rebooted and popped back up successfully; a good time to hit the Prodrive gym and unwind a bit!

There is nothing more permanent than a temporary solution

Pros and cons

You are in control, free to choose your project and role

A lot of freedom in your work, matched with responsibility where you can pick the level you are comfortable with

Great facilities: good gym, free lunch & dinner

The coffee seems to be the only thing exempt from the high Prodrive quality standards

The Prodrive Technologies Mindset

Responsibility

You don’t just go to work, you feel responsible for your project

Flexible

You decide when, where and how much you want to work

Manufacturing

You like to think about manufacturability when designing

Initiative

You don’t sit and wait, you have a hands-on mentality

What we offer

- Perfect environment for those eager to develop themselves and take full responsibility for a project.

- Many opportunities for personal and professional development, along with the flexibility to explore diverse roles across various projects.

- A young and dynamic culture which stimulates innovative thinking and taking initiatives.

- Personal budget just for you to learn new things. Your growth is our priority.

- Flexible working hours and lunch, dinner, and access to our company gym.

- Personalized development plan to craft your future.

- You will receive essential tools if these are necessary to perform your job (i.e. iPhone and laptop).

- On-campus sports facilities enable you to incorporate exercise seamlessly into your work routine.

- A performance-driven salary that grows with your accomplishments.

- Unlock the opportunity to become a shareholder and entrepreneur within the company.

- Travel allowance based on the days you are actually at Prodrive Technologies.

- Work-life balance with at least 33 vacation days per year.

- Access a retirement plan.

Application steps

- Your journey with us starts with a swift review of your application by one of our recruiters.

- In some cases, if we see a potential fit, you will receive an exclusive link to our online aptitude test to assess if you’re up for the challenge.

- We will schedule a personal interview not only to determine if your skills match the job, but also to see if there is a spark between you and Prodrive Technologies.

- To complete the application journey we will send you a suitable offer and once you sign, we can welcome you to the Prodrive Technologies family.