What many people don’t realize is that the power modules used in so many power conversion products largely determine its lifetime and reliability. Manufacturers are therefore faced with a choice between performance, cost, and dependability based on the power module.

A range of standard power modules is already available off-the-shelf, but there is now an emerging trend towards choosing power modules that are designed specifically for each application.

Ahead of APEC 2022 and PCIM Europe, where Prodrive Technologies will present its portfolio of bespoke power modules and the technologies that go into them, our experts explain what is driving demand, and why these custom solutions may be a better option for many product manufacturers.

What is driving growth for custom power modules?

Most product manufacturers have, until now, sourced generic power modules that are “OK” for the application, but always require some sort of compromise. In many cases, they need to overdesign a solution to achieve the desired power. The best a customer can aim for in this scenario is to select a solution requiring the least amount of dies (power transistors), leading to cost savings, or where the modules are more reliable and long-lasting.

However, what we have seen is growth in several areas where manufacturers are realizing the potential of a customized power module solution for their products. Several possible applications are driving this demand:

This need is further cemented by other factors affecting the power market more generally. Semiconductor performance is increasing fast (driven by the transition from Si to SiC and GaN), and the packaging is becoming a limiting factor to getting the highest performance out of these dies.

Generic power modules are not problem-free

It is a fact that power modules suffer from thermal stresses whenever they are switched on or off (i.e. they heat up). The dies in modules can dissipate a significant amount of heat which leads to the materials in the package heating up rapidly and cooling.

The thermal swing causes stress in and between the materials because their coefficients of thermal expansion typically don’t match. This is one of the main reasons that power modules will fail in time and is, therefore, a driving force for manufacturers in seeking custom solutions tailored to tackle their particular use case.

How to optimize power modules

There are multiple routes for optimizing the die packaging in highly integrated power modules. Such as:

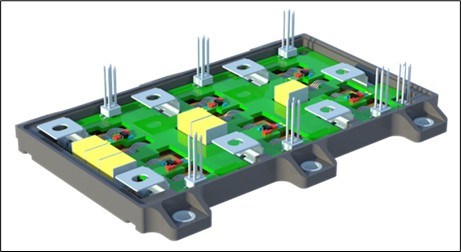

Render of a 3.6 kV multi-level power module with 3D integrated driver and passive components.

Integration of electrical components into the module

On the electrical side, integrating components into the module, which are typically found on PCBs (printed circuit boards) outside the module, allows critical parameters to be optimized. For example, integrating the decoupling and snubbers enables the optimization of the power loop.

Meanwhile, integrating the gate driver and utilizing a kelvin source terminal allows for optimal gate drive loops, leading to higher efficiency and less ripple.

Mechanical optimization to exceed off-the-shelf solution performance

Mechanical optimization can be done through the choice of die attach layers, insulating materials, and heat spreaders, for example, in order to tune the thermal behavior of the module and greatly increase cycles-to-failure compared to standard solutions.

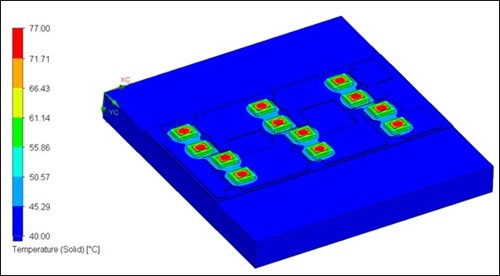

FEM transient thermal simulation of a simplified module on a cooling infrastructure to estimate transient thermal performance.

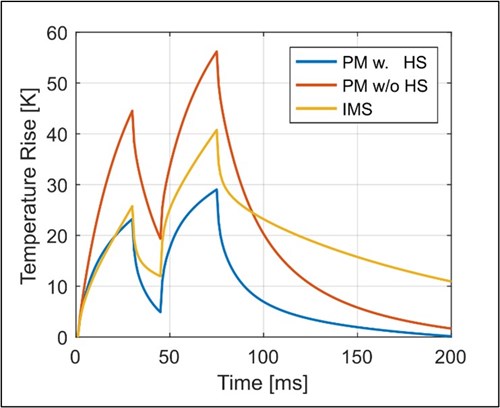

FEM transient thermal simulation results of a simplified module on a cooling infrastructure showing the thermal response of a custom power module consisting of a ceramic substrate with and without heat spreader versus a discrete on an IMS board for a given equal load profile.

These solutions can lead to higher lifetime or higher power density when using the same die, or alternatively to lower cost for the same performance by using lower rated dies.

At Prodrive Technologies, we combine multiple solutions in our own custom Si IGBT and SiC MOSFET power modules.

Customized power modules help you make better products

By selecting a technology based on the application, it is possible to optimize the performance, reliability, and cost target for each module. Custom power modules are also typically more compact as they are designed specifically for an application, offering the shortest loops for the smallest parasitics. The much smaller commutation loop that Prodrive Technologies can achieve is largely possible by smart integration of the passive components into the module.

For our customers, this means they can produce and market a superior product that’s more reliable at the right price while minimizing design effort and time-to-market. For instance, where two standard power modules are normally used together, challenges related to balancing are introduced. Instead, a single customized solution could be used. This typically reduces overall cost.

How Prodrive Technologies creates custom power modules

Prodrive Technologies has developed a toolbox of various production technologies to suit different applications and provide high volume customized production, including:

One of the most notable is a method of sintering the die instead of soldering the die and sintering topside instead of wire bonding. A sintered layer leads to a bond with high thermal stability, high thermal and electrical conductivity, superior mechanical properties, thinner bond lines, and uniform heat spreading.

So, whether the application demands soldering or sintering of dies, Prodrive Technologies can use different technologies for interconnections. Options such as wirebonding, ribbon bonding, and top side sintering can be selected to meet any specification.

This toolbox of options also offers the flexibility to design the module according to the form factor desired, with freedom of topology choice, at the power density required.

All die materials such as Si, SiC, and GaN, or combination, can be utilized.

As well as delivering a smaller commutation loop, an additional benefit is that the solutions from Prodrive Technologies can use better distribution of power to the different dies, thereby preventing that one die will heat up more and thereby fail earlier.

With Prodrive Technologies, product manufacturers benefit from a customized design that is more reliable than standard modules, with better performance and the volumes they need at a competitive price.

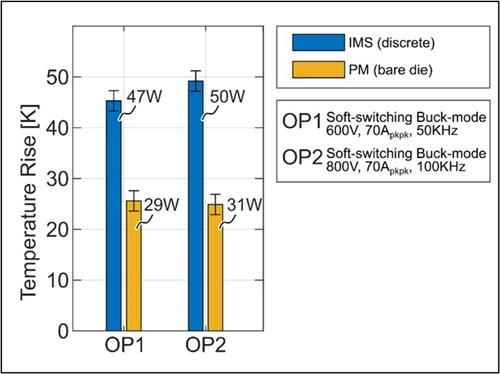

Measurement results showing both the electrical performance increase (i.e. decreased losses) for the power module compared to the discretes on IMS board, combined with the thermal performance indicated by their temperature rise for two operating points OP1 and OP2. Both operating points are steady state operation points, showing that the performance increase aimed at short timescales also benefit in steady state operation.

Designed for thermal performance and suited for high volume production

Design, qualification, and manufacturing can be done completely in-house by Prodrive Technologies to meet relevant automotive and industrial standards.

We manufacture custom power modules to ensure stable production parameters and quality. Furthermore, if requested, Prodrive Technologies is capable of taking responsibility for wider system and cooling design or integration.

Prodrive Technologies will be showing custom power modules at the most important electronics shows in Europe and the US:

Come and meet our team of experts at the show or contact us for more information on your custom power module requirements.