At Prodrive Technologies we have a passion for technology and strongly believe in supporting the growth of ambitious students. Therefore, we are very proud to be sponsor of team University Racing Eindhoven, URE in short. Prodrive Technologies is actively involved because the team shows the passion and ambition to push the boundaries of electric vehicle racing, while studying at the university. This is exactly where young Prodrivers are born.

University Racing Eindhoven is a student team of the TU/e with 60 enthusiastic members. Every year, URE builds a new electric racing car to compete in Formula Student, the largest international design competition. Every summer the team is competing in races all over Europe. This year TT Assen, Circuit de Catalunya and the Hockenheimring were planned for the races. To compete with the top, the team has to be innovative. The car has a carbon fibre monocoque and uses four-wheel drive for maximum acceleration, accelerating from 0 to 100 km/h in just 2.3 seconds!

To understand more of the car, URE develops almost all components on its own, where partners like Prodrive help with this design process and the production. Since 2017, URE has also been working on driving autonomous and created the first autonomous racing vehicle in the Benelux. The vehicle can be converted from electric to driverless and vice versa, making it the only convertible vehicle of the competition.

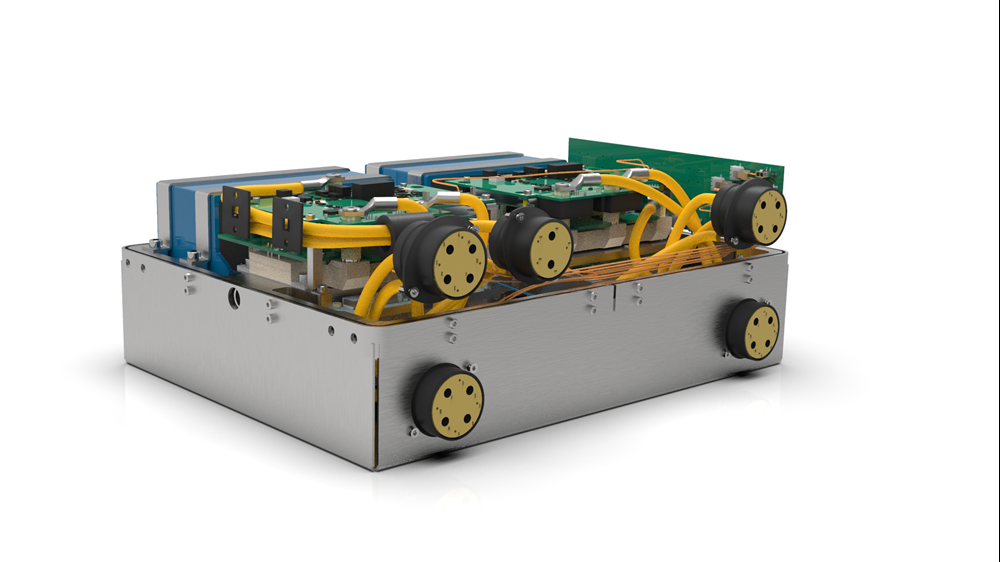

The collaboration between URE and Prodrive goes back a couple of years. The two best examples of this collaboration are the high voltage battery management system (HV BMS) and the high voltage motor controller (inverter). These components are key components in the electric powertrain of the URE cars.

The HV BMS is responsible for measuring and processing all the important signals in the HV battery and using these signals to ensure the safety of the battery and the system. Apart from managing the safety, the HV BMS is also used the balance the battery which is an important function. The BMS consists of several components. There is one central module (BMS master board) which, amongst other things, manages the communication with the car and controls the HV isolation relays. Measuring the temperature and voltages of the battery is done by so called ‘BMS slave boards’ which are in direct contact with the master board.

The HV motor controller is connected to the HV BMS. The most important function of the motor controller is to converter the DC current from the battery to AC current that we use to control our motors. To be able to do this the motor controller also has to measure and process the motor position and run the motor control model. The motor control model runs at a high frequency. Every cycle it determines the best way to control the motors to get the best performance.

URE wouldn’t be an ambitious student team if it isn’t continuously innovating. URE has learned a lot all the past projects, races and the collaboration with Prodrive. Apart from that there are new innovations which enable more technical possibilities compared to several years ago. Therefore, URE will redesign the car’s powertrain and cooperate with Prodrive Technologies, making use of the expertise, production capabilities and high-tech lab equipment on site. The powertrain will be finished before the competition start of 2022.